The on-board programmable automation controller is Rockwell Automation's latest Logix device. Topics including Sensors, Control Loops, Ladder Logic Programming, Industrial Ethernet, HMI, Networking, lock-out/tag outs, and enhanced PID tuning are all explored within the included curriculum.

ControlsLabTM comes equipped with pre-installed Rockwell Automationprogramming software (FactoryTalk View ME and Studio 5000) and allows students to devise real-world, custom industrial process scenarios. No additional hardware or software is required.

This affordable, yet turnkey system consists of the following primary components:

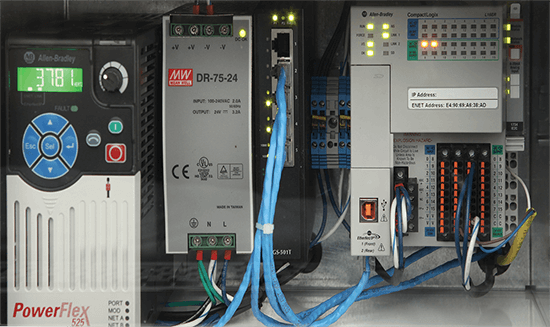

Programmable Process Automation Controller (PAC) Ladder logic with PIDE Autotune, alarms, lock-out tag out, etc.

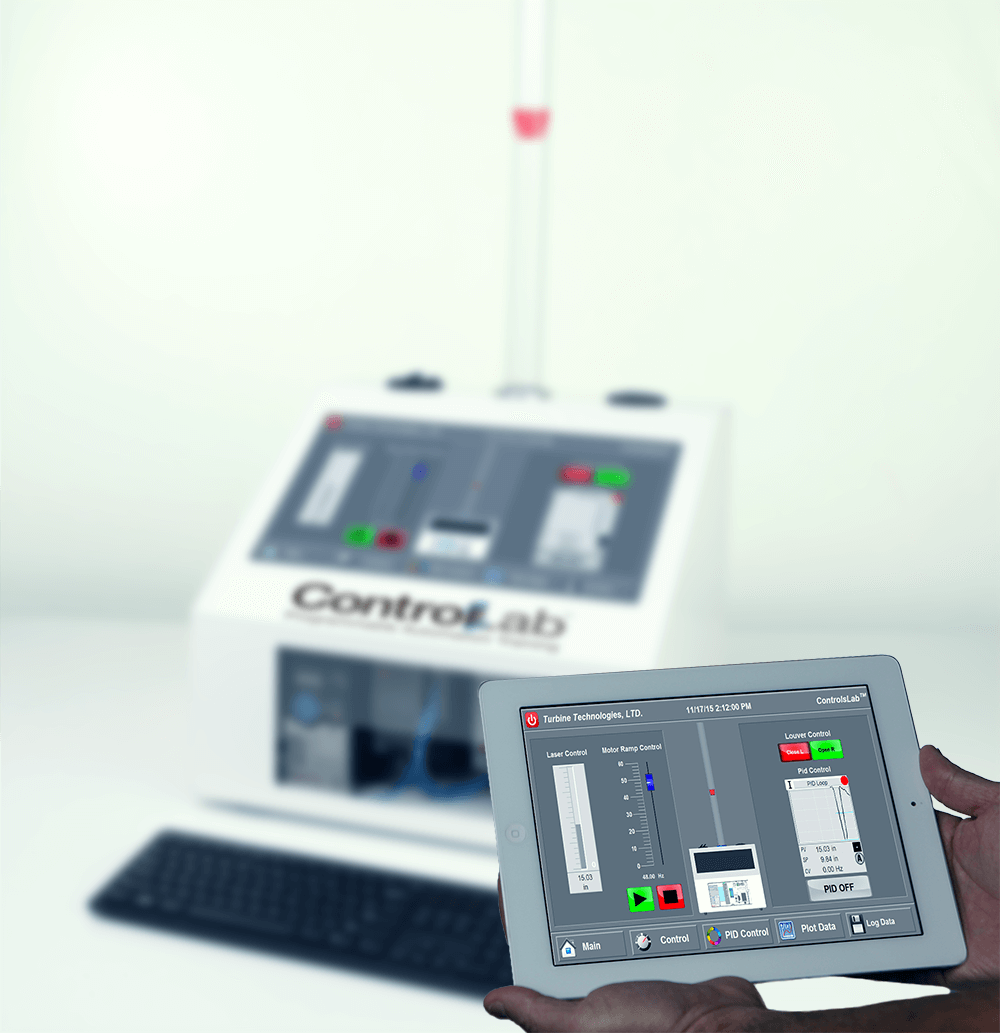

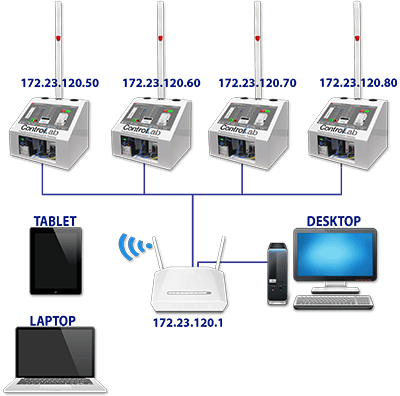

On-board, pre-configured Wi-Fi for remote & LAN operation with multiple classroom units

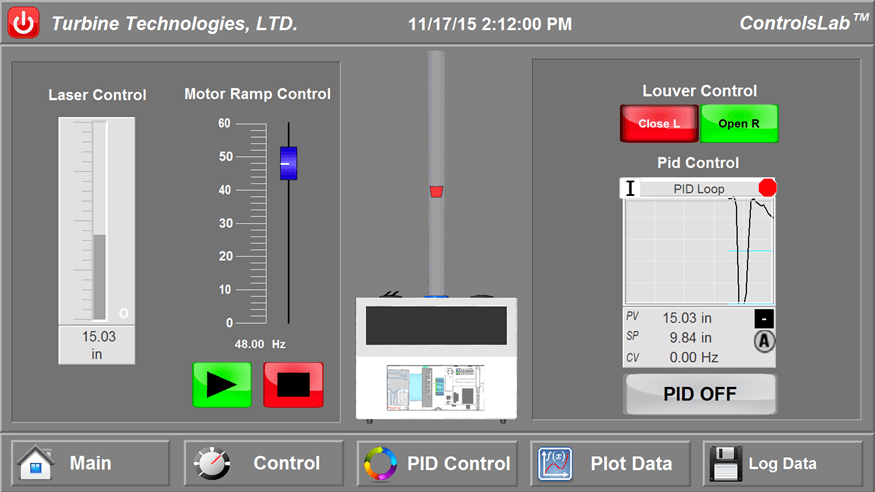

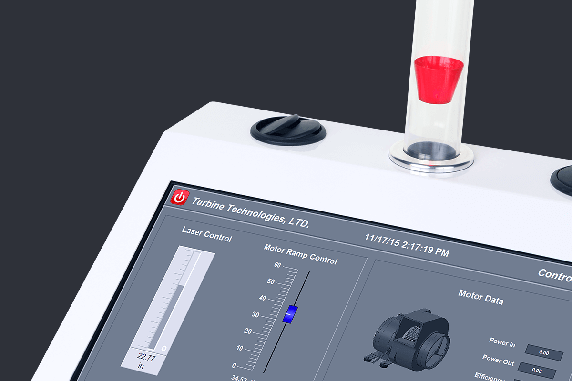

Human Machine Interface (HMI) Pre-installed virtual instrument screens for out-of-the-box, real-time monitoring of motor performance characteristics along with manual & PIDE motor control. Custom, open-ended design of instrumentation & process automation scenarios made available by on-board Rockwell Factory Talk View ME V 8.0 & Studio 5000. Featuring a large format, 20-inch color touch screen

Comprehensive Free Curriculum

Variable Frequency Drive (VFD)

Photoelectric Laser Sensor

3-Phase Air Blower

Dual Solenoid-Actuated Air Louvers

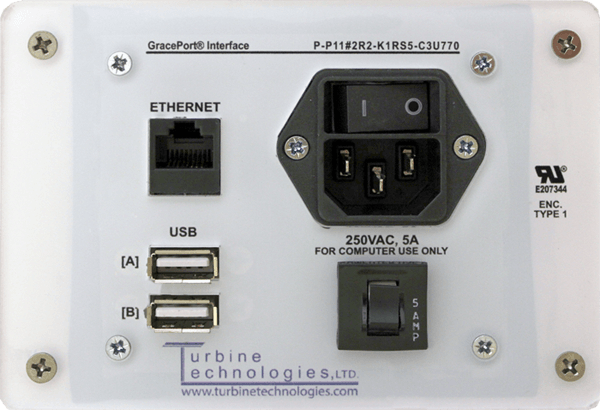

Convenient Wall Power & Data Connectivity